Prior to the five C’s of diamonds -- cut, clarity, color, carat weight, and certification -- there were more subjective reasons that determined a diamond’s price. Perhaps the most common was size. We have since been able to look back at those reasons from our new standardized position and see just how that lack of standards led buyers astray.

Just as with diamonds, orthodontic wires should now be evaluated by a standardized measure for quality. Wire quality is sternly dictated by key features and characteristics and less by subjective or inconsequential reasoning. Unlike diamonds, wires serve a functional role and as such, their benefit from this standardization is not simply improved aesthetics, but increased reliability in their performance. There are different wire considerations across all stages of the treatment process. We will focus here on proposed standards for the first stage of treatment: alignment and leveling.

First Stage Orthodontics: Alignment and Leveling

The first stage of orthodontic treatment involves unraveling crowded teeth and moving them into the desired positions, regardless of whether teeth have been extracted or not. This is essential for the treatment to progress properly. The wire is the physical driver that makes alignment and leveling possible, and with the variety of wires available, there are currently many different outcomes due to wire choice. To ensure more consistent patient outcomes, there is a growing demand for how to assess wires prior to their use. This eliminates guesswork that goes into the alignment and leveling processes and guarantees results consistent with the treatment plan.

Wire Quality Standards in the First Stage: Our Three R's

Wire quality in the first stage of orthodontic treatment essentially boils down to the capability of the wire. Can it do the job of aligning and leveling? Can it do the job well? These may sound like simple considerations, but they are critical in determining the effectiveness of a wire, and there are three key factors that go into creating and maintaining this effectiveness.

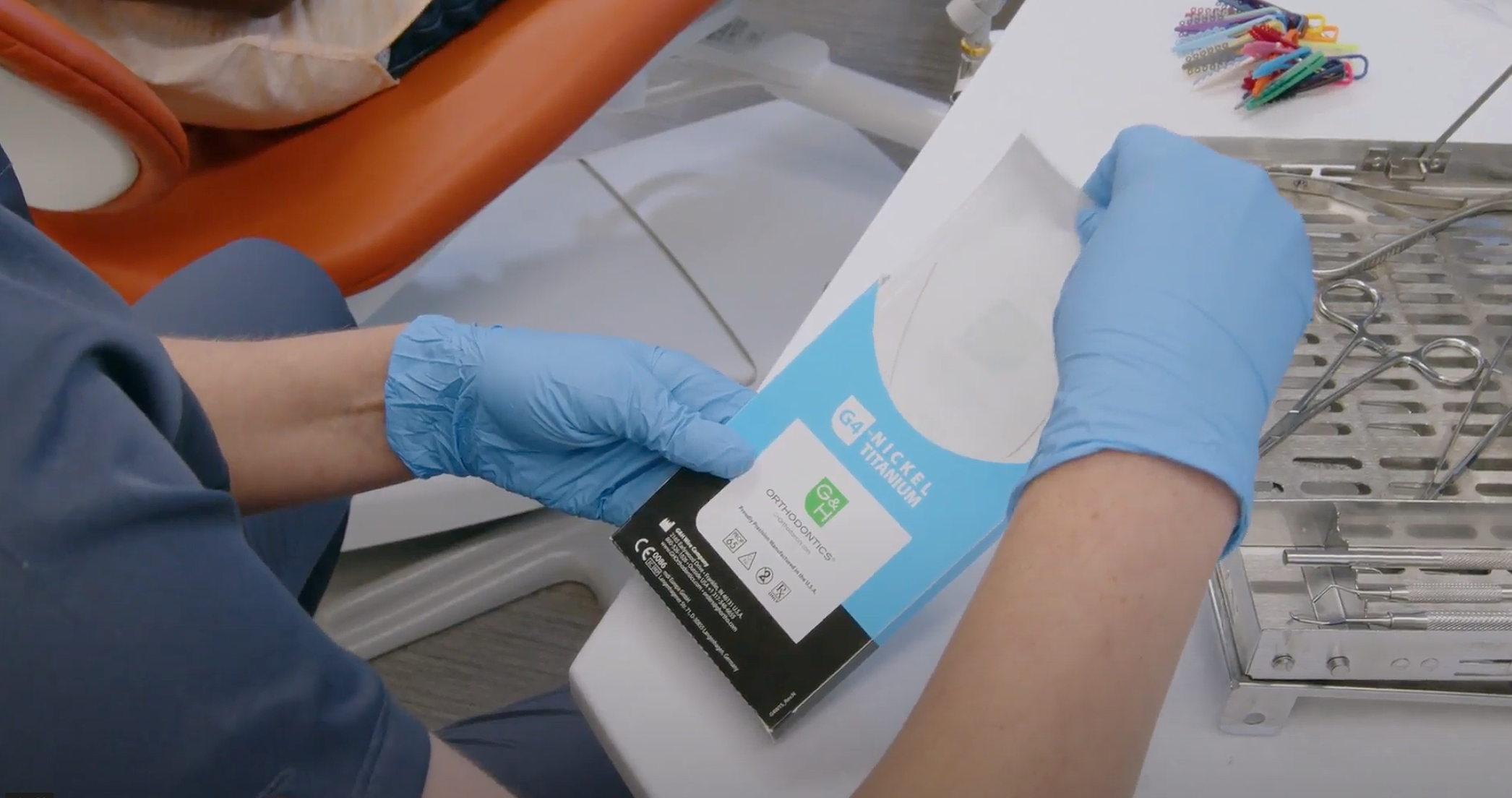

RANGE: The first factor to be considered is the degree of pliability or spring-back the wire has. Alignment and leveling, especially coming from initially very crowded teeth, means the wire must seamlessly stretch the range between brackets. The wire must then work smoothly from this initial distorted position to the archform shape that has been stored in its memory. This range of movement back to the original shape is what straightens the teeth. A wire with great range is only possible when the alloy it is composed of has specific properties. This alloy, a blend of nickel and titanium known as nitinol, is what makes it possible for the wires to perform this function. When manufacturers use the best raw materials and processes for forming their wires, the wires will provide the range necessary to achieve desired outcomes for the initial stages of treatment.

ROBUSTNESS: Another factor that must be considered is the actual force the wire provides to move the teeth, as light and continuous forces are required to properly treat patients. Appropriate wire strength will allow the proper amount of force while not creating any concerns for excessive PDL stress or patient discomfort. Craftsmanship in wire forming and tight controls in the manufacturing processes allow a manufacturer to consistently deliver a wire that will be robust for the many weeks of treatment time and the range of movement the teeth will require, with the precision of force that gives the optimal treatment desired for the patient.

RIGIDITY: The last consideration for wires in alignment and leveling is the rigidity of the wire. This may seem like a contradiction when we just spoke about how important full range is for the initial stage. However, rigidity is essential when considering the dimension and form of the wire. Early in the treatment, the brackets will move a great deal across the surface of the wires. Consequently, the wires must have good rigid qualities to allow solid sliding mechanics to occur. Binding, kinks, and damage to the wire would all hinder these sliding mechanics. Dedication to perfecting materials and continuously improving processes allows manufacturers to develop a product that can have incredible range and deliver the needed rigidity simultaneously.

When combined, the three R’s of range, robustness, and rigidity create a new standard for how wires are manufactured and selected by orthodontists. Much like the five C’s of diamonds, these three standards create an objective definition of quality. As opposed to aesthetics or packaging, the quality of a wire is directly tied to its functionality and consistency. Diamonds may be a girl’s best friend, but quality wires are a patient’s best friend. And though wires themselves may not get the attention they deserve, a straight smile always does.

Leave a Comment