Our most recent blog covered a recommended standard for orthodontic wires in the early stage of treatment: the three R’s of robustness, rigidity, and range. These characteristics help the wire efficiently move teeth from their misaligned positions into the desired archform, with a leveled occlusal plane. But the work of the wires does not stop there. In the late stage of treatment, or working and finishing, wires shift teeth into their final desired positions for optimal occlusion. Different stages require different standards, and for treatment to finish strong, the following three wire characteristics should be assessed: strength, stiffness, and pliability.

Late Stage Orthodontics: Working and Finishing

The late stage of orthodontic treatment is comprised of two elements: working and finishing. Working brings the bite into its correct antero-posterior orientation and involves moving teeth as a segment so the arches line up correctly. If there are spaces in the arch, such as from extractions, this is the stage where the spaces are closed. Finishing completes treatment by bringing all teeth into their correct angle and putting the final touches on proper alignment; consider it the details of creating that beautiful smile. As with early stage treatment, it is critical to pick the best wire for these stages.

Wire Quality Standards in the Late Stage of Treatment

Wires truly have a lot of work to do in this stage of treatment, which is why the term “working” is an accepted part of orthodontic vernacular. To do this work effectively and progress to the finishing stage, wires must have the proper strength, stiffness, and pliability.

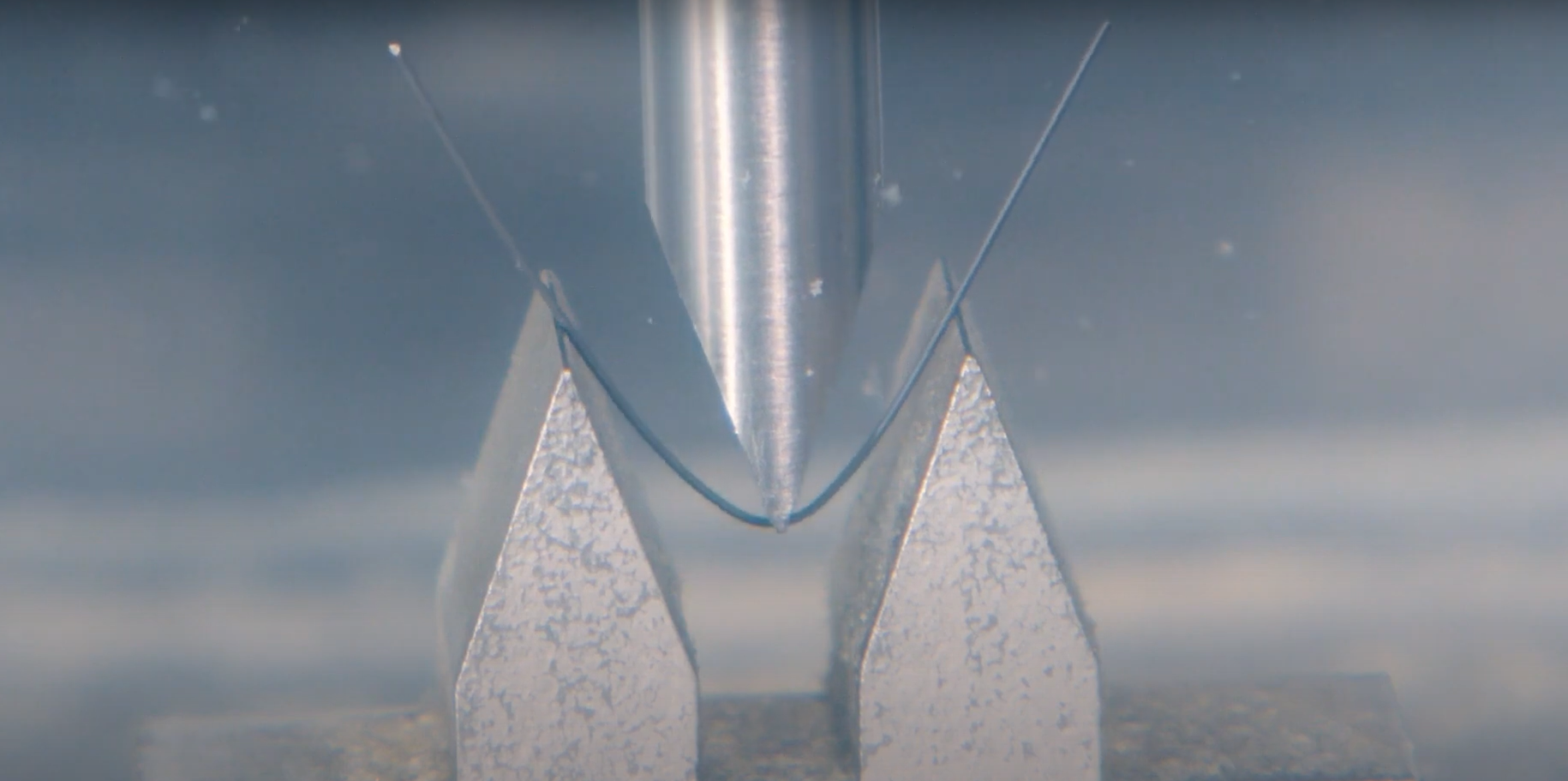

Strength can be defined as the ability of the wire to withstand force before breaking. The wires used during late stage treatment must be stronger than those used in previous stages. It is critical to understand that the manufacturing process can create either a strong wire or a brittle one depending on factors like the application of work and/or heat. Either excessive heat or heat applied at the wrong time during manufacturing can result in a brittle wire that breaks under with little force. It is important to ask your wire supplier what steps they are taking or avoiding in the manufacturing process to maintain the wire strength needed for working and finishing.

As with strength, stiffness will be the highest it has been during treatment thus far. We must know how much the wire gives before popping back to its original shape. Without the correct wire stiffness, maintenance of the shape created during aligning and leveling will be at risk. The strength and stiffness requirements for working and finishing often dictate a shift from nickel titanium to stainless steel. Although stainless steel is highly regulated to maintain consistency of materials, quality of workmanship will always affect the quality and performance of the final product. Being familiar with the integrity of the supplier’s manufacturing process is the best way to ensure that the wire performs once in the hands of the orthodontist and in the mouth of the patient.

The final consideration for wires during the late stage of treatment is pliability, or the wire’s ability to accept a bend. Can you work with the wire to create the bends needed for detailing? And will the wire hold that bend for the time necessary to create the needed change in tooth angle or spacing?

All three considerations for late stage wires come down to the production methodology. When manufactured to a high level of precision through multiple quality inspections, wires will have the correct strength, stiffness, and pliability during the working and finishing stages to leave the patient with the beautiful smile they’ve been waiting for.

To learn more about the 28-point inspection process G&H uses to manufacture wires, please visit https://shop.ghorthodontics.com/pdf/assets/brochure-wires-how-its-made.pdf.

Leave a Comment